Your specialist for parallel keys …

Give us a call. We will be pleased to advise you.

fon: +49 (0)2391 91796–0

fax: +49 (0)2391 91796–30

Parallel Keys

All types available in all materials and with or without heat treatment.

Parallel Keys

All types available in all materials and with or without heat treatment.

Form A

- round end

- made to DIN 6885

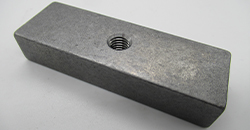

Form B

- square end

- made to DIN 6885

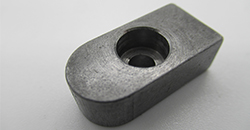

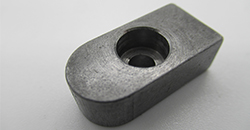

Form AB

- one end round

- one end square

- made to DIN 6885

Form C

- round end

- with hole for retaining screw

- made to DIN 6885

Form CD

- one end round

- one end square

- with tapped hole for forcing screw

- also available in special versions

Form D

- square end

- with hole for retaining screw

- made to DIN 6885

Form AS

- round end

- with tapped hole for forcing screw

- made to DIN 6885

Form ABS

- one end round

- one end square

- with tapped hole for forcing screw

- also available in special versions

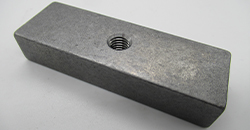

Form BS

- square end

- with tapped hole for forcing screw

Form EOS

- round end

- with holes for two retaining screws

- also available in special versions

Form E

- round end

- with holes for retaining screws

- with tapped hole for forcing screw

- made to DIN 6885

Form F

- square end

- with holes for retaining screws

- with tapped hole for forcing screw

- made to DIN 6885

Form A

- round end

- made to DIN 6885

Form B

- square end

- made to DIN 6885

Form AB

- one end round

- one end square

- made to DIN 6885

Form C

- round end

- with hole for retaining screw

- made to DIN 6885

Form CD

- one end round

- one end square

- with tapped hole for forcing screw

- also available in special versions

Form D

- square end

- with hole for retaining screw

- made to DIN 6885

Form AS

- round end

- with tapped hole for forcing screw

- made to DIN 6885

Form ABS

- one end round

- one end square

- with tapped hole for forcing screw

- also available in special versions

Form BS

- square end

- with tapped hole for forcing screw

Form EOS

- round end

- with holes for two retaining screws

- also available in special versions

Form E

- round end

- with holes for retaining screws

- with tapped hole for forcing screw

- made to DIN 6885

Form F

- square end

- with holes for retaining screws

- with tapped hole for forcing screw

- made to DIN 6885

MORE FACTS ON OUR PARALLEL KEYS

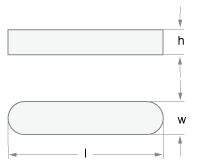

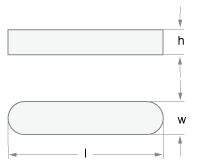

| Width | w | 2 — 150 mm |

| Height | h | 8 — 80 mm |

| Length | l | 4 — 700 mm |

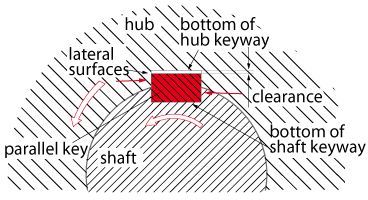

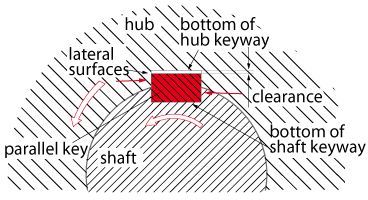

A parallel key connection is used to effect a shaft-hub connection (see picture). It is the most commonly used form-locking connection for pulleys, gear wheels and couplings with shafts with predominantly one-sided torque load. This type of connection is cost-effective, easy to mount and easy to release. The parallel key sits in the shaft and hub keyway and acts as a driver but, in contrast to the structurally similar slot wedge connection, is only load-bearing laterally, the rear surface having a degree of play. Parallel key connections are pure drive-type connections. In contrast to the wedge connection, the parts are not clamped firmly together. There must always be clearance between the parallel key and the bottom of the hub keyway (see picture). The parallel lateral surfaces of the parallel key lie against the lateral surfaces of the shaft and hub keyway and so transmit the torque load between shaft and hub through a tight fit. The parallel key functions by surface pressure and shearing. To avoid the permissible strength values being exceeded, the length of the parallel key should be at least 1.2 times greater than the diameter of the shaft.

A parallel key connection is used to effect a shaft-hub connection (see picture). It is the most commonly used form-locking connection for pulleys, gear wheels and couplings with shafts with predominantly one-sided torque load. This type of connection is cost-effective, easy to mount and easy to release. The parallel key sits in the shaft and hub keyway and acts as a driver but, in contrast to the structurally similar slot wedge connection, is only load-bearing laterally, the rear surface having a degree of play. Parallel key connections are pure drive-type connections. In contrast to the wedge connection, the parts are not clamped firmly together. There must always be clearance between the parallel key and the bottom of the hub keyway (see picture). The parallel lateral surfaces of the parallel key lie against the lateral surfaces of the shaft and hub keyway and so transmit the torque load between shaft and hub through a tight fit. The parallel key functions by surface pressure and shearing. To avoid the permissible strength values being exceeded, the length of the parallel key should be at least 1.2 times greater than the diameter of the shaft.

The advantages of a parallel key connection are its high accuracy, the central location of the hub, the lack of canting and tensioning, the lack of any need to fit and drive in as with wedges and the resulting lack of damage to the components (important if rolling bearings are being built in). The only real disadvantages are that the hubs must be additionally protected against axial displacement and their vulnerability to mutual torque. The advantages, however, significantly outweigh the disadvantages.

The standards for parallel keys by pattern and dimensions are set by DIN 6885. The picture below shows the different patterns of parallel keys delivered by Crummenerl GmbH.

Custom dimensions and patterns are possible. DIN 6885 also stipulates that a fit with the tolerance field P9, N or JS9 in accordance with DIN 7155 must be used for the tolerance of the slot width. The parallel key therefore is equivalent to a uniform shaft with tolerance position h (upper deviation = 0). The bases for the design and calculation of parallel key connections are set out by DIN 6892. Parallel keys in pattern A and B are available with tapped holes for forcing screws, patterns E and F also without such tapped holes. In patterns E and F the forcing screw is located to one side and not centrally. This enables leverage, which facilitates the release of the parallel key from the slot.

The most commonly used material today is C45K. Crummenerl GmbH manufactures parallel keys in this material in large quantities but also makes them from 34CrNiMo6, 42CrMo4 (for greater load-bearing), Nirosta and other special alloys. In special cases, titanium alloys are also used. Adherence to factory standards and special heat treatments are standard to us

Dimensions available

Width w

2 — 150 mm

Height h

8 — 80 mm

Length l

4 — 700 mm

Customer dimensions available on agreement.

Also available in inch dimensions.

A parallel key connection is used to effect a shaft-hub connection (see picture). It is the most commonly used form-locking connection for pulleys, gear wheels and couplings with shafts with predominantly one-sided torque load. This type of connection is cost-effective, easy to mount and easy to release. The parallel key sits in the shaft and hub keyway and acts as a driver but, in contrast to the structurally similar slot wedge connection, is only load-bearing laterally, the rear surface having a degree of play. Parallel key connections are pure drive-type connections. In contrast to the wedge connection, the parts are not clamped firmly together. There must always be clearance between the parallel key and the bottom of the hub keyway (see picture). The parallel lateral surfaces of the parallel key lie against the lateral surfaces of the shaft and hub keyway and so transmit the torque load between shaft and hub through a tight fit. The parallel key functions by surface pressure and shearing. To avoid the permissible strength values being exceeded, the length of the parallel key should be at least 1.2 times greater than the diameter of the shaft.

A parallel key connection is used to effect a shaft-hub connection (see picture). It is the most commonly used form-locking connection for pulleys, gear wheels and couplings with shafts with predominantly one-sided torque load. This type of connection is cost-effective, easy to mount and easy to release. The parallel key sits in the shaft and hub keyway and acts as a driver but, in contrast to the structurally similar slot wedge connection, is only load-bearing laterally, the rear surface having a degree of play. Parallel key connections are pure drive-type connections. In contrast to the wedge connection, the parts are not clamped firmly together. There must always be clearance between the parallel key and the bottom of the hub keyway (see picture). The parallel lateral surfaces of the parallel key lie against the lateral surfaces of the shaft and hub keyway and so transmit the torque load between shaft and hub through a tight fit. The parallel key functions by surface pressure and shearing. To avoid the permissible strength values being exceeded, the length of the parallel key should be at least 1.2 times greater than the diameter of the shaft.

The advantages of a parallel key connection are its high accuracy, the central location of the hub, the lack of canting and tensioning, the lack of any need to fit and drive in as with wedges and the resulting lack of damage to the components (important if rolling bearings are being built in). The only real disadvantages are that the hubs must be additionally protected against axial displacement and their vulnerability to mutual torque. The advantages, however, significantly outweigh the disadvantages.

The standards for parallel keys by pattern and dimensions are set by DIN 6885. The picture below shows the different patterns of parallel keys delivered by Crummenerl GmbH.

Custom dimensions and patterns are possible. DIN 6885 also stipulates that a fit with the tolerance field P9, N or JS9 in accordance with DIN 7155 must be used for the tolerance of the slot width. The parallel key therefore is equivalent to a uniform shaft with tolerance position h (upper deviation = 0). The bases for the design and calculation of parallel key connections are set out by DIN 6892. Parallel keys in pattern A and B are available with tapped holes for forcing screws, patterns E and F also without such tapped holes. In patterns E and F the forcing screw is located to one side and not centrally. This enables leverage, which facilitates the release of the parallel key from the slot.

The most commonly used material today is C45K. Crummenerl GmbH manufactures parallel keys in this material in large quantities but also makes them from 34CrNiMo6, 42CrMo4 (for greater load-bearing), Nirosta and other special alloys. In special cases, titanium alloys are also used. Adherence to factory standards and special heat treatments are standard to us

Contact

Contact form

Contact details

Bannewerthstr. 18

58840 Plettenberg

Germany

Crummenerl GmbH (goods receiving / goods issue / truck access)

Bannewerthstr. 24c

58840 Plettenberg

Germany

Phone: +49 2391 91796–0

Fax: +49 2391 91796–30

Mail: info@crummenerl-gmbh.de

Web: www.crummenerl-gmbh.de

Contact details

Crummenerl GmbH (Office)

Bannewerthstr. 18

58840 Plettenberg

Germany

Crummenerl GmbH (goods receiving / goods issue / truck access)

Bannewerthstr. 24c

58840 Plettenberg

Germany

Phone: +49 2391 91796–0

Fax: +49 2391 91796–30

Mail: info@crummenerl-gmbh.de

Web: www.crummenerl-gmbh.de

Contact form