Your specialist for parallel keys …

Give us a call. We will be pleased to advise you.

fon: +49 (0)2391 91796–0

fax: +49 (0)2391 91796–30

Your specialist for parallel keys …

Give us a call. We will be pleased to advise you.

fon: +49 (0)2391 91796–0

fax: +49 (0)2391 91796–30

Parallel Keys

We manufacture all common types of keyways according to DIN 6885, company standards, and custom dimensions — in all standard materials, with or without heat treatment. We also meet special requirements with customized heat treatment processes. Our extensive range of machinery with state-of-the-art CNC milling technology ensures flexible and cost-efficient production.

All versions available in all materials, with or without heat treatment.

Key Details About Our Parallel Keys

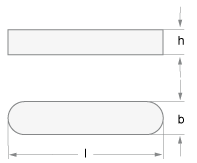

Available Dimensions

| Width | w | 2 - 150 mm |

| Height | h | 8 - 80 mm |

| Length | l | 4 - 700 mm |

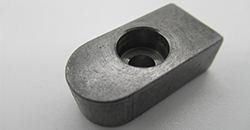

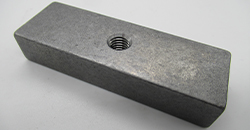

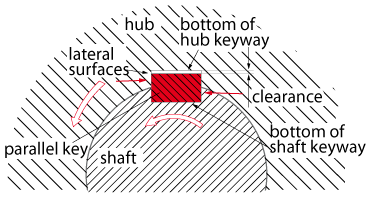

A parallel key connection is used to create a shaft-hub connection (see image). It is the most common type of positive-locking connection for pulleys, gears, and couplings on shafts with predominantly one-directional torque loads. This type of connection is cost-effective, easy to assemble, and simple to disassemble.

The key, which sits in the shaft and hub keyways, acts as a torque transmitter. Unlike the similar-looking keyed connection, the parallel key only transmits torque via its side faces — the back face of the key has clearance. Parallel key connections are pure torque-transmitting joints. In contrast to wedge keys, the parts are not clamped together. There must always be clearance between the key and the bottom of the hub keyway (see image). The parallel side faces of the key engage with the keyway flanks in the shaft and hub, transmitting torque by form-fit. The key is subjected to surface pressure and shear forces. To stay within permissible strength limits, the key length should be at least 1.2 times the shaft diameter.

Advantages of parallel key connections include high precision, true concentricity of the hub, no wedging or jamming, and no need for fitting or driving in as with wedge keys — resulting in gentler handling of components (especially important when roller bearings are used). The only drawbacks are the need for additional axial locking of the hub and their sensitivity to alternating torques. However, these disadvantages are far outweighed by the benefits.

Parallel keys are standardized in form and dimension according to **DIN 6885**. The image below shows the various key types supplied by Crummenerl GmbH.

Custom dimensions and forms are available. DIN 6885 also stipulates that a tolerance fit with field P9, N9 or JS9 per **DIN 7155** must be used for the keyway width. This makes the key part of a “standard shaft system” with tolerance zone **h** (upper limit = 0). The design and calculation fundamentals for key connections are defined in **DIN 6892**.

Keys of form A and B are available with threaded holes for ejector screws; forms E and F can also be delivered without them. For forms E and F, the ejector screw is positioned laterally instead of centrally, allowing for a lever effect that facilitates key removal.

The most commonly used material today is **C45K**. Crummenerl GmbH produces parallel keys in large volumes also from **34CrNiMo6**, **42CrMo4** (for higher loads), **stainless steels (Nirosta)**, and other special alloys. In special cases, **titanium alloys** are also used. Compliance with company standards and the use of special heat treatments are part of our standard offering.

Please complete the form below and we will help you as quickly as possible. The form is also available as a pdf file to download, complete and fax to us.

Contact

Contact form

Contact Details

Crummenerl GmbH (Office)

Bannewerthstr. 18

58840 Plettenberg

Germany

Crummenerl GmbH

(goods receiving / goods issue / truck access)

Bannewerthstr. 24c

58840 Plettenberg

Germany

Phone: +49 (0)2391 91796–0

Fax: +49 (0)2391 91796–30

E-Mail: in**@*************bh.de

Web: www.crummenerl-gmbh.de

Contact

Contact Form

Contact Details

Crummenerl GmbH (Office)

Bannewerthstr. 18

58840 Plettenberg

Germany

Crummenerl GmbH

(goods receiving / goods issue / truck access)

Bannewerthstr. 24c

58840 Plettenberg

Germany

Phone: +49 (0)2391 91796–0

Fax: +49 (0)2391 91796–30

E-Mail: in**@*************bh.de

Web: www.crummenerl-gmbh.de